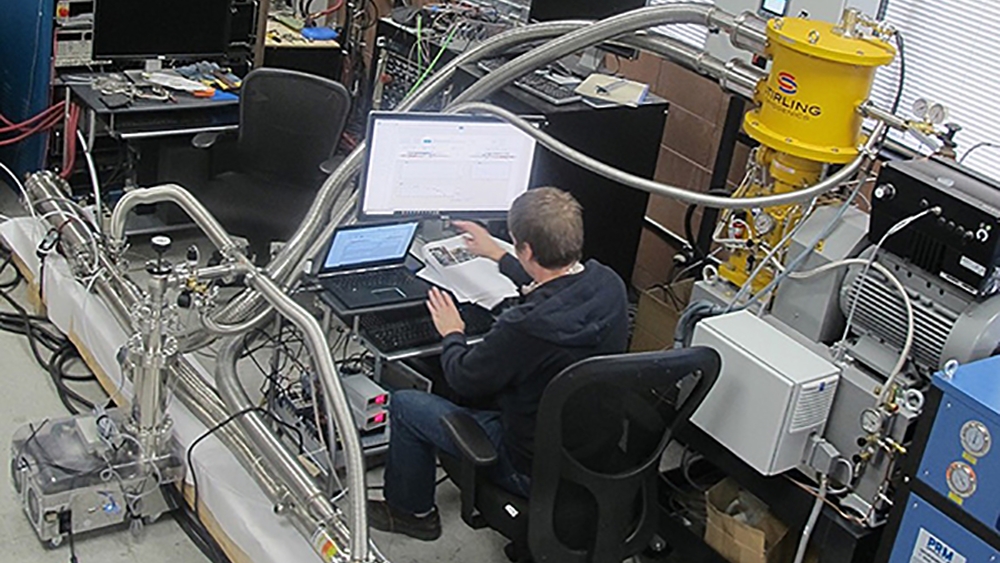

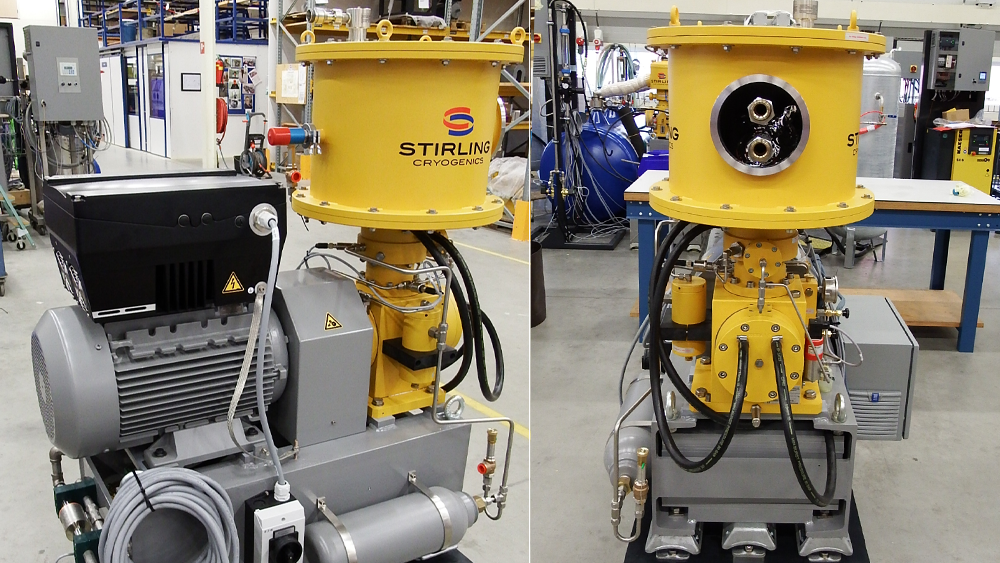

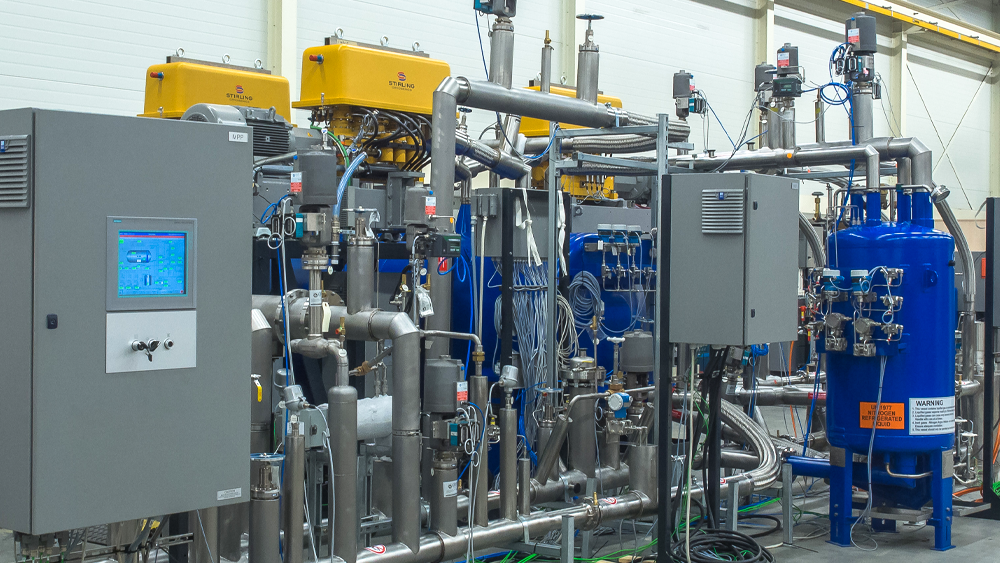

> Cryogenerators

> LNG production plants

> LNG BOG management systems

> Liquid hydrogen plants

> Liquid nitrogen production systems

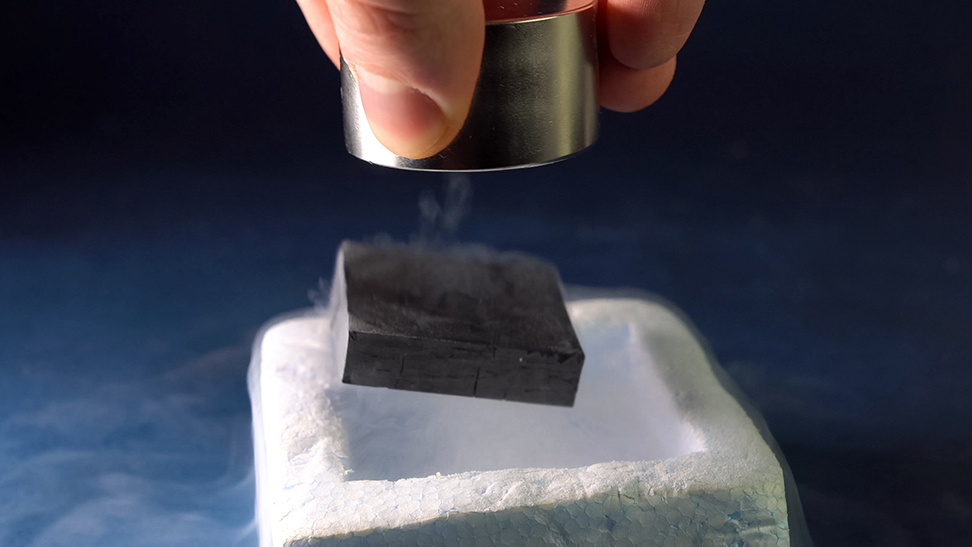

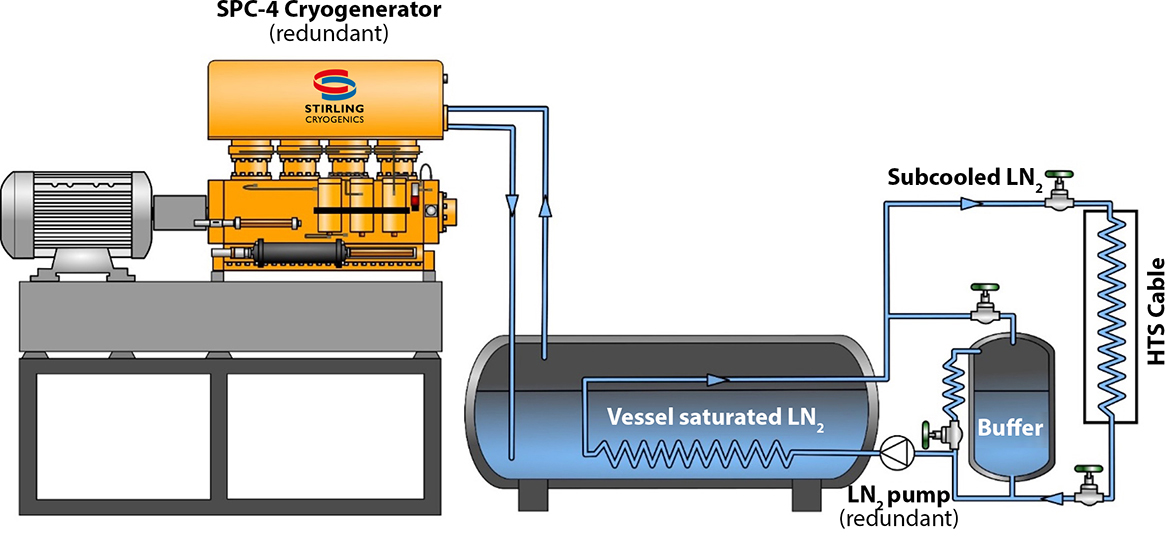

> Systems for Superconductivity

> Liquid oxygen systems

> Closed Loop Cooling Systems

> Cryogenic fans

> Cryogenic pumps

> LNG production plants

> LNG BOG management systems

> Liquid hydrogen plants

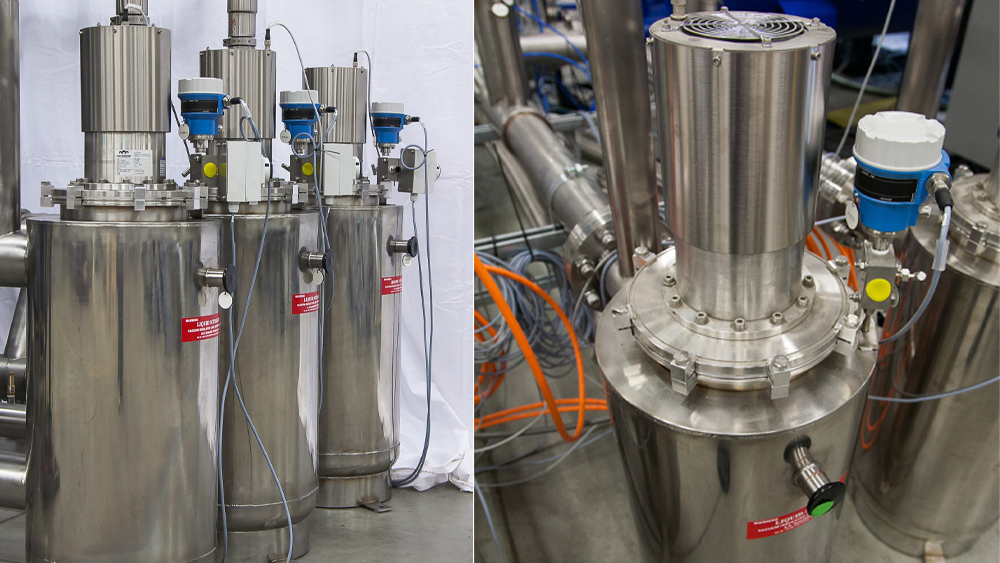

> Liquid nitrogen production systems

> Systems for Superconductivity

> Liquid oxygen systems

> Closed Loop Cooling Systems

> Cryogenic fans

> Cryogenic pumps

> LNG Production

> LNG BOG Management

> Liquid hydrogen

> Bio Storage

> Research & University

> Healthcare

> Superconductivity

> Food & Beverage

> Aerospace

> LNG BOG Management

> Liquid hydrogen

> Bio Storage

> Research & University

> Healthcare

> Superconductivity

> Food & Beverage

> Aerospace

> Artificial Insemination Centre, Botswana

> La Honda, Venezuela

> Bovine Al, Nicaragua

> Vet Agro Sup, France

> La Honda, Venezuela

> Bovine Al, Nicaragua

> Vet Agro Sup, France

> Memorial University Newfoundland, Canada

> University of Otago, New Zealand

> CEA, Fontenay-aux-Roses France

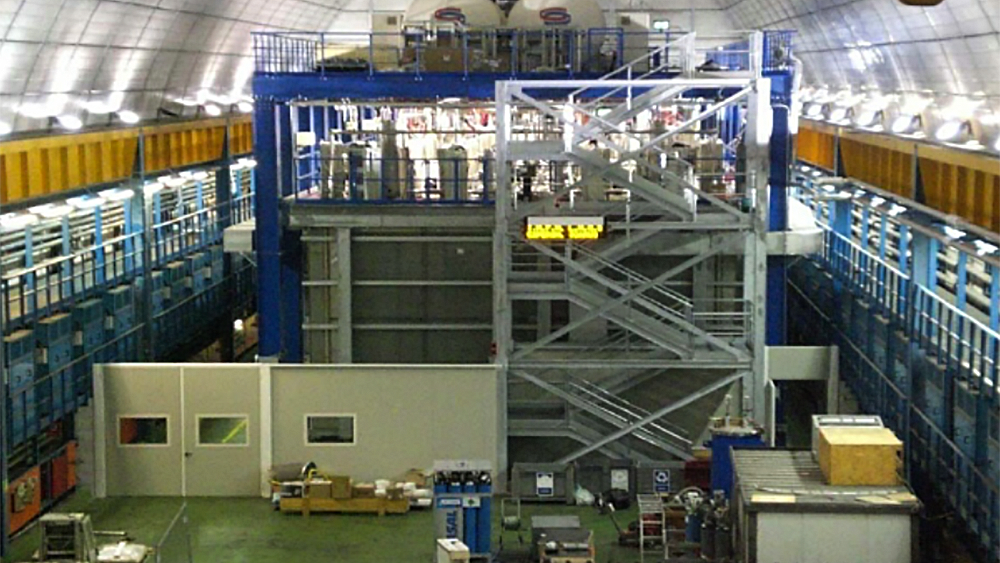

> INFN, Italy

> Snolab, Sudbury Canada

> Instituto de Ecologia, Xalapa Mexico

> IVIC, Venezuela

> Isaac Newton Group of Telescopes, La Palma Spain

> Atacama Large Millimeter Array, Chile

> CNEA, Bariloche Argentina

> Nuclear site of Chernobyl, Ukraine

> RV Sonne, Germany

> RV Maria Merian, Germany

> University of Otago, New Zealand

> CEA, Fontenay-aux-Roses France

> INFN, Italy

> Snolab, Sudbury Canada

> Instituto de Ecologia, Xalapa Mexico

> IVIC, Venezuela

> Isaac Newton Group of Telescopes, La Palma Spain

> Atacama Large Millimeter Array, Chile

> CNEA, Bariloche Argentina

> Nuclear site of Chernobyl, Ukraine

> RV Sonne, Germany

> RV Maria Merian, Germany

Head office:Stirling Cryogenics BV

Science Park Eindhoven 5003

5692 EB Son, The Netherlands

T +31 40 26 77 300

info@stirlingcryogenics.com

Offices in:USA

T +1 610 714 9801

usa-office@stirlingcryogenics.com

Germany

T +49 171 1795 994

germany-office@stirlingcryogenics.com

Sweden

T +46 766 111 728

sweden-office@stirlingcryogenics.com

Head office:Stirling Cryogenics BV

Science Park Eindhoven 5003

5692 EB Son, The Netherlands

T +31 40 26 77 300

info@stirlingcryogenics.com

Offices in:USA

T +1 610 714 9801

usa-office@stirlingcryogenics.com

Germany

T +49 171 1795 994

germany-office@stirlingcryogenics.com

Sweden

T +46 766 111 728

sweden-office@stirlingcryogenics.com